3kHz Elastomer Test System (NEW)

With the introduction of electric vehicles, there are increasing requirements for sound and vibration standards, and product standards are becoming more stringent. To meet this growing demand, we have launched the 3kHz Elastomer Test System. This system is capable of measuring a wide range of dynamic parameters, including the static spring constant, decay coefficient, and loss tangent. Featuring thermostatic baths, a soundproof chamber, precision measurement jigs, and a variety of other optional accessories, this system robustly supports the development of products that require high-frequency measurements up to 3 kHz.

KCH701-50 3kHz Elastomer Test System

|

Dynamic force

|

±15kN

|

|

Pre-load

|

0~5kN

|

|

Max. stroke

|

±20mm

|

|

Max. velocity

|

1000mm/s

|

|

Frequency range

|

DC~3kHz

|

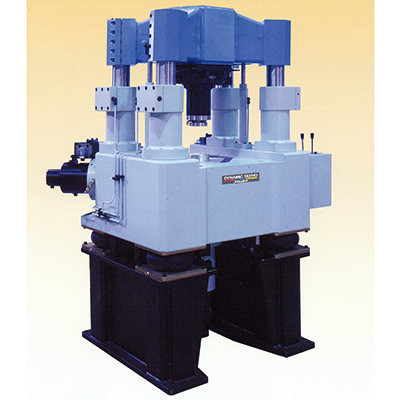

Triaxial Elastomer Test System

This system simultaneously triaxially vibrates and measures the dynamic characteristics of anti-vibration components.

KCH703-30 Triaxial Elastomer Test System

|

X, Y, Z axis max. force

|

20kN

|

|

X, Y, Z axis max. displacement

|

±15mm

|

|

Max. velocity

|

35cm/s

|

|

Frequency range

|

0.1 to 200Hz

|

Elastomer Test System

This system is designed to measure the dynamic characteristics of engine mounts and other anti-vibration rubber components.

KCH701-30 1kHz Elastomer Test System

|

Max. force

|

20kN

|

|

Max. displacement

|

±25mm

|

|

Max. velocity

|

±50cm/s

|

|

Frequency range

|

0.1 to 1000Hz

|

KCH701-20 300Hz Elastomer Test System

|

Max. force

|

20kN

|

|

Max. displacement

|

±30mm

|

|

Max. velocity

|

±50cm/s

|

|

Frequency range

|

0.1 to 300Hz

|

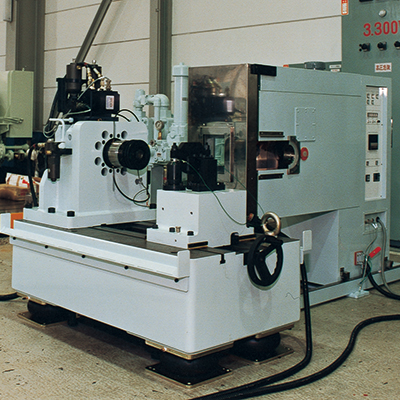

Torsional Elastomer Test System

This system is designed to measure the dynamic torsional characteristics of anti-vibration rubber components.

KCH702-10 Torsional Elastomer Test System

|

Max. torque

|

±2000N・m

|

|

Max. angle

|

±20°

|

|

Max. anglar velocity

|

±1000°/s

|

|

Frequency range

|

10 to 500Hz

|

Torsional Damper Test System

With this test system, the resonance point of a torsional damper is measured on the production or inspection line, and pass/fail judgments are made. The resonance frequency is then determined from both the torque cell output in the vibration head unit and the peak frequency of the acceleration output gain.

KCH702-11 Torsional Damper Test System

|

Max. torque

|

±2000N・m

|

|

Max. angle

|

±20°

|

|

Max. anglar velocity

|

±1000°/s

|

|

Frequency range

|

10 to 500Hz

|

Elastomer Inspection Test System

This system is designed to test the dynamic characteristics of anti-vibration components in the production process.

KCH701-1 Elastomer Inspection Test System

|

Max. force

|

5 or 10kN

|

|

Max. displacement

|

±50mm

|

|

Max. velocity

|

±15cm/s

|

|

Frequency range

|

0.1 to 100Hz

|